I. Product Introduction:

It is suitable for building the module and terminal test solution platform for smart phone, WI-FI, Bluetooth, smart grid equipment, automotive electronics, drones, smart home and other fields. The shielding box is made by more than ten strict processes, such as CNC machining, electrostatic spraying and baking paint, assembling and debugging, testing and inspection. It has the advantages of high shielding efficiency, reliable structure and stable performance.

serial number

Part Name

serial number

Part Name

1

Door handle (manual closing/opening)

6

Network port interface RJ45

2

a handle for a suitcase

7

M6 intake port

3

AC220Vsocket (for electric plug)

8

Banana (constellation)

4

USB2.0 connector

9

In-Place Sensor

5

DC connector

10

control box

II. Technical guidance

|

serial number |

sports event |

Brief description of content |

|

1 |

shielding effect |

433MHz-6GHz≥75dB |

|

2 |

Interface Type |

DC*2; USB2.0*3; RJ45*1; DB9*3; Ø6 trachea port*2; Banana head*2 |

|

3 |

Number of filter openings |

4PCS,Spare port reserved for 2PCS |

|

4 |

control method |

manually operated |

|

5 |

operating temperature |

Normal temperature operation |

|

6 |

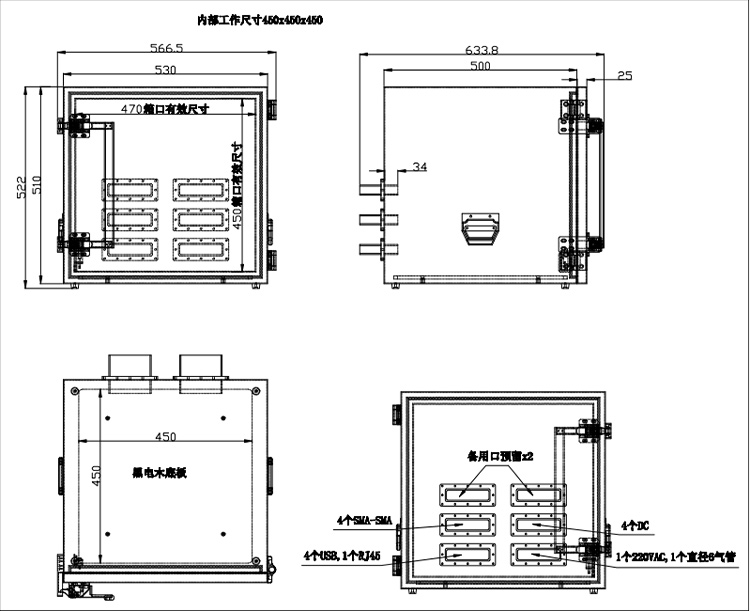

Box size |

550(W)*500(D)*550(H)mm |

|

7 |

working size |

490(W)*440(D)*490(H)mm |

|

8 |

Overall dimensions |

600(W)*650(D)*650(H)mm,Including footrest height, interface length |

|

9 |

Effective size of box opening |

490(W)*440(H)mm |

|

10 |

exterior color |

Baked Corrugated White |

|

11 |

Main features |

①All data ports and power signals are EMI filtered. |

Ⅲ. shielding box operation process:

Shielding box manually open → manual loading → shielding box manually close → shielding test start → shielding test completed → shielding box manually open.

IV. Daily maintenance:

1. Before using the shielding box, please read this manual carefully and verify the gas source to ensure that the air pressure is in the range of 0.4~0.6Mpa.

2. Shielding box should be placed on a smooth work surface and grounding, ventilation and dryness around the box to ensure that the lid open and close the range of activities without blocking, interference, while avoiding strong heat sources and strong electric/magnetic sources to ensure that the shielding effect of the shielding box and the operation of the safe and stable.

3. According to the test requirements to build a test platform, in order to avoid inconsistencies between the test platform equipment indirect grounding potential difference, while contacting or connecting different equipment electrocution, the equipment must use three-pronged plug and grounding good socket, grounding requirements of the equipment must be well grounded.

4. In the shielding box operation, it is strictly prohibited to stack items on it, so as to avoid items slipping and damage, in the shielding box closing process, be sure to operate with both hands, prohibit the use of hands or other items to block the opening and closing action of the shielding box.

5. shielding box in the case of unused, should be cleaned up the box of debris, and then the shielding box work in the closed box state, the switch is in a state of disconnection, so that the next use.

6. shielding box in the case of long-term non-use, should do a good job of dust and moisture, shall not pile up debris in the box above, to avoid damage to the shielding box, affecting the shielding effect and stability of the shielding box.

7. box surface and box wave-absorbing materials can be used to wring out the warm cloth or dipped in alcohol to clean, can not be used to chemically clean Je, in order to avoid damage to the box paint or wave-absorbing materials, affecting the service life of the product and the effect of the box must maintain a dry environment, such as accidentally poured into the liquid, should be cleaned up in a timely manner.

8. Use a clean cloth with a small amount of mild detergent to scrub regularly, do not use abrasives or solvents. Regularly clean each RF port, the power supply interface is easy to retain more dust, when cleaning, pay attention to be discharged after.

Ⅵ.shielding box common problems and treatment methods:

|

serial number |

Shielded Box Problem Points |

Troubleshooting |

|

1 |

Reduced shielding characteristics |

1. Cause analysis: excessive dust or dirt on the conductive cotton. Treatment: the first electrode connecting line and jigs and fixtures, etc. unloaded, followed by a neat cotton cloth will be conductive cotton on the dust and dirt scrubbing neat or cleaner blow clean, conductive cotton on the prohibition of the application of cold water, ethanol, abrasive and other liquids to carry out the cleanup.

|

|

2 |

loose fitting connector |

Reason analysis: There is too much dust inside the interface or there is metal oxide in the corner of the needle. Processing method: first of all, the electrode connecting line and jig and so on uninstalled, with a neat soft brush slowly shell inside and outside the interface of the dust cleaned out, and then with a neat soft brush dipped into a small amount of pure alcohol to clean up a piece of, Note: the interface is prohibited from applying other liquids to carry out the cleanup. |

VII. List of wearing parts and replacement cycle:

1, conductive cotton, replacement cycle of 6 months, according to the actual use of replacement

Shielding effect test report

Equipment number :88002081

Equipment name :Shielding box PB0309

Device specification :550(W)*500(D)*550(H)MM

Test date : May 22, 2023

Recommended recalibration date (Next Cal):

Test Equipment (ReRequired Equipment)

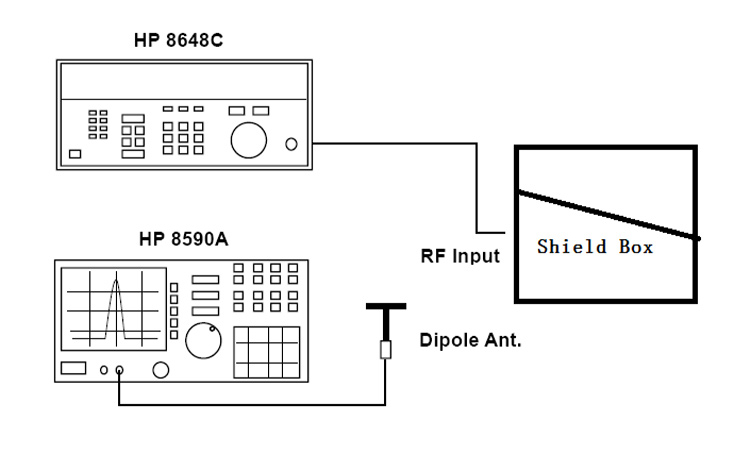

1. Spectrum Analyzer: HP8590A.

2. Signal Generator: HP8648C.

3.Dipole Antenna: TESCOM 900MHz, 1.8GHz, 2.4GHz, 5.8GHz.

4.Dipole Antenna: TESCOM 900MHz, 1.8GHz, 2.4GHz, 5.8GHz.

Test Procedure:

Shielding Effectiveness Measurement.

Standardization: 433MHz-6GHz≥75dB.

2. Shield Effect

|

Frequency(MHz) |

Shield Effect(dB) |

Limit(dB) |

Pass/Fail |

|

433MHz |

78 |

≥75 |

Pass |

|

900MHz |

78 |

≥75 |

Pass |

|

2.4GHz |

76 |

≥75 |

Pass |

|

5.8GHz |

75 |

≥75 |

Pass |